20

Aug 20th, 2025

Picture this: A heavily traveled rural road is in decent condition but showing signs of wear, such as light cracking, surface ruts and a history of crack sealing. What’s the next move?

For Jake Lough, Highway Superintendent of Montgomery County, IN, the answer was clear: cape seal, a two-step treatment combining chip seal with a final layer of micro surfacing. The choice was not made on instinct alone. Lough has completed the PPRA’s Road Resource “Roadvocate” training, equipping him with a proactive network management mindset grounded in data, cost-efficiency and long-term performance.

“Pavement preservation is important to me because I have witnessed firsthand the consequences of neglecting regular maintenance on a roadway network,” shares Lough.

He summarizes his learnings, saying, “Without timely intervention, deterioration accelerates and leads to significantly higher costs and more extensive repairs. Pavement preservation offers a relatively low-cost solution that extends the service life of roads by maintaining them in good condition, rather than following a “worst-first” approach, which often leads to a costly and unsustainable cycle of deferred maintenance.”

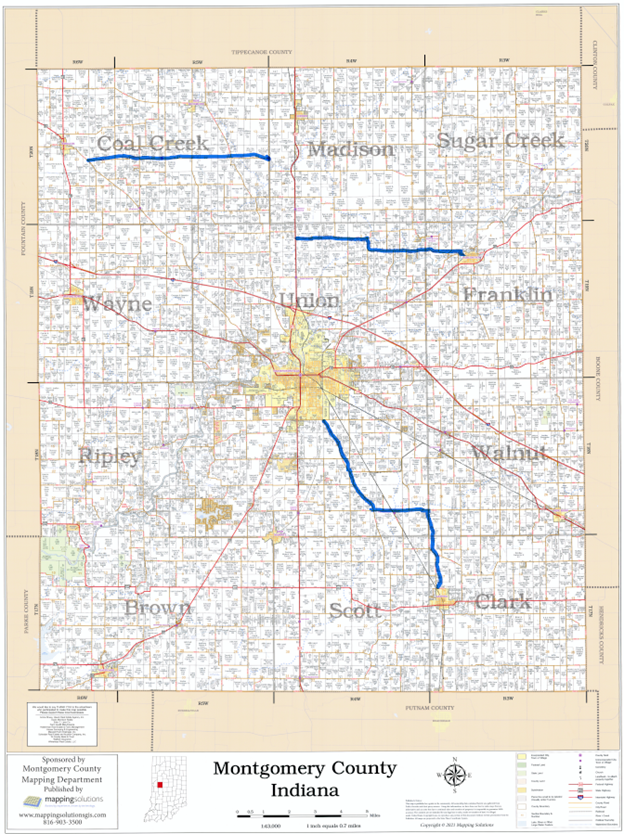

Montgomery County’s team selected cape seal for several rural routes based on high traffic volume, PACER ratings and treatment history. The addition of micro surfacing over chip seal offers enhanced durability, better ride quality and improved moisture protection. Cape seal is an ideal fit to meet the performance demands of these roads that are still in fair condition but at risk of accelerating decline.

Project Snapshot

Chip seal is among the most cost-effective preservation methods. It involves applying a layer of asphalt binder, followed by aggregate (stone chips). As traffic passes over the surface and pneumatic rollers embed the aggregate, the treatment locks in place.

An experienced crew can cover around five miles per day. Best of all, roads can reopen to local traffic almost immediately after application.

Step 1: Oil Distributor, AE-90S (a polymer-modified, anionic emulsion)

Step 2: Chip Spreader, 11 Stone, CSS-1HL Type A Stone, high quality hard stone known for its reduced emulsion absorption resulting in a lower cost, while maintaining road durability

Close up of chip seal ……………………………………………. One of two pneumatic rollers to embed the aggregate

After the chip seal is fully compacted, a layer of micro surfacing is applied. This mixture is made of polymer-modified asphalt emulsion, fine aggregate, water, additives and cement. The materials are prepared at a nearby staging site, then loaded into a custom micro surfacing paver.

Staging Site: Aggregate is processed for the micro mixture and CSS-1HL (a cationic emulsion) is hooked up for transfer to the paver

On the Road: Cement is poured in, and the pugmill combines asphalt, aggregate, water and cement into a final hot mix

Inside the paver’s mixing chamber, the components are combined with cement before being evenly spread across the chip-sealed surface. Squeegees and burlap cape help smooth the surface texture. Cure time is minimal, often just 1–2 hours before traffic can resume.

Evergreen Roadworks’ Pavement Maintenance Systems crew precisely applies the micro surfacing

The final result is a uniform, dark-colored surface with improved skid resistance. The treatment protects the road surface against oxidation, moisture infiltration and further surface degradation. With proper timing and application, cape seal can extend the life of a roadway by 8–10 years.

“As a result, valuable taxpayer dollars can be redirected toward improvements on other roads within the network, maximizing the overall efficiency and impact of available funding,” Lough notes.

According to the PPRA, cape seal can reduce life cycle costs by up to 25%, compared to traditional hot mix asphalt (HMA) overlays. This treatment also requires 15% less energy than an HMA overlay, with 30% reduced greenhouse gas emissions.

Road Condition Before Cape Seal and After Treatment Completion

Evergreen Roadworks’ pavement preservation team brings decades of expertise to every job. Their Pavement Maintenance Systems division has been applying micro surfacing since the 1980s, making them one of the Midwest’s most experienced contractors for this treatment combination.

This depth of experience shows in the results. Smooth, consistent application, tight traffic coordination and minimal disruption are all hallmarks of a seasoned crew.

Chip seal crew members ……………………………………….. Micro surfacing crew members

Another differentiator: Evergreen Roadworks is backed by the resources of Heritage Construction + Materials — a vertically integrated family of companies that support projects from materials to execution.

This connected network allows for better material compatibility, quality control and innovation on every project.