11

Aug 11th, 2025

Evergreen Roadworks™ puts sustainability and cost savings into action on IDOT’s IL-133, using Cold In-Place Recycling to rehabilitate aging pavement with less material, less disruption and longer-lasting results.

America’s aging roadways are showing their wear, but full reconstruction is not always the answer. That is why transportation agencies across the country are turning to a smarter, more sustainable approach: Cold In-Place Recycling (CIR).

This summer, Evergreen Roadworks completed a CIR project for the Illinois Department of Transportation (IDOT) on IL-133 in Edgar County, giving the pavement new life without the cost and carbon footprint of a full rebuild.

Cold In-Place Recycling is an efficient method of rehabilitating pavement that mills the existing pavement, processes it, then repaves, all without leaving the road. Rather than hauling away old asphalt millings and trucking in new mix, CIR uses a specialized train of equipment to:

1) Mill the top 2-5 inches of existing asphalt into a consistent blend of recycled asphalt pavement (RAP)

2) Mix the RAP with a recycling agent, often foamed asphalt or an asphalt emulsion, plus other additives

3) Pave and compact the CIR mix back on the roadway

The result: a rejuvenated base layer that corrects surface distress and delays reflective cracking, all while saving time, materials and emissions. Once complete, a final wearing course (such as chip seal, micro surfacing or a thin hot mix asphalt overlay) is applied to protect the recycled layer.

While recycling asphalt has been around since the mid-1900s, modern CIR gained momentum in the 1970s amid rising oil prices and the arrival of more advanced milling equipment. Early adopters discovered that combining existing pavement with emulsified or foamed asphalt produced a strong, long-lasting base.

Today, CIR is used in more than half of U.S. states (source 1, 2) . Thanks to decades of monitoring and performance data, it is a trusted solution that delivers measurable savings and durability.

States with particularly strong CIR programs include Indiana, Wisconsin, Virginia, California, North Carolina, Colorado, Montana, Utah, Kansas and Oregon. Illinois is steadily expanding its use as well.

In the summer of 2025, Evergreen Roadworks™ partnered with IDOT and Howell Paving, Inc. to rehabilitate more than 213,000 square yards of IL-133 pavement, using Cold In-Place Recycling. This treatment addressed underlying distress while improving ride quality and extending the life of the pavement structure.

Evergreen Roadworks performed 213,161 square yards of Cold In-Place Recycling, including:

*For this project, Evergreen used Asphalt Materials, Inc. AMICYCLE ™ Cold In-Place Recycling. The mix design and quality control were supported by their partners from Heritage Research Group.

Once the recycled base reached a moisture content of 2% or less, a polymerized hot mix asphalt binder and surface course were paved over the base by the prime contractor — typically within two weeks.

To ensure long-term durability of the centerline joint, Evergreen also applied Longitudinal Joint Sealant (LJS) — known outside of Illinois as Void Reducing Asphalt Membrane (VRAM). The seasoned team was able to cover 83,722 linear feet (14.3 miles) in just over 6 hours.

LJS/VRAM is applied in an 18” wide band before the surface course and fills air voids from the bottom up, preventing moisture and oxygen intrusion. Studies show it can extend the life of centerline joints by 3 to 5 years, reducing maintenance needs and costs. Learn more about VRAM here.

LJS/VRAM application, then 1.5” HMA surface course paved on top of LJS by Howell Paving

Cold In-Place Recycling has been proven to reduce costs, cut emissions and extend pavement life, making it a proven solution for agencies seeking efficient, low-disruption road rehabilitation. For an agency perspective, explore this article on another IDOT CIR project.

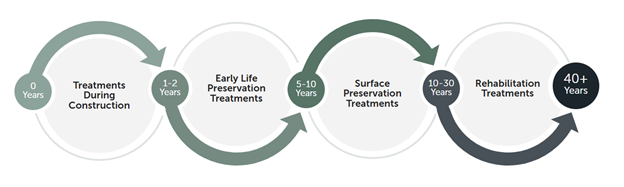

But CIR is just one part of a larger pavement preservation strategy. With the right combination of treatments over time, roads can achieve 40+ years of serviceable life at a lower total lifecycle cost.

If you are new to pavement preservation, or exploring options for your network, check out this free resource, or contact Evergreen Roadworks. We are a full-service preservation contractor serving the Midwest, and we are here to help.