13

Nov 13th, 2024

On every road that is made of more than one lane, there are longitudinal joints. These parallel joints are the interface between two asphalt mats where one lane of hot mix asphalt (HMA) is laid next to an existing lane or shoulder.

Take a close look at the longitudinal joints on many roads today. Unfortunately, deteriorated longitudinal joints are a common sight, as they are typically the first part of a pavement to fail. This systemic issue does not just affect the joints – it leads to the rapid failure of the entire pavement, creating both safety hazards and costly repairs for the public.

With the goal of developing safer, longer-lasting roadways, some of the leading minds in the asphalt industry collaborated to find a better solution. The result is the void reducing asphalt membrane (VRAM), also known as longitudinal joint sealant (LJS) in Illinois. This innovative, materials-based approach to road construction allows longitudinal joints to stand the test of time.

VRAM offers a proactive solution, extending the service life of pavement at a lower overall cost by reducing the need for subsequent maintenance and preventing road failure. By mitigating these issues, road crews can avoid unsafe repair work along the centerline joint, and the public benefits from safer, more reliable roads.

Evergreen Roadworks is the largest applicator of J-Band®, the premier VRAM. Over the years, Evergreen’s teams from Illiana and ProTack have sprayed J-Band on hundreds of projects across the Midwest. The project detailed below is an excellent example of how J-Band is integrated into typical HMA construction.

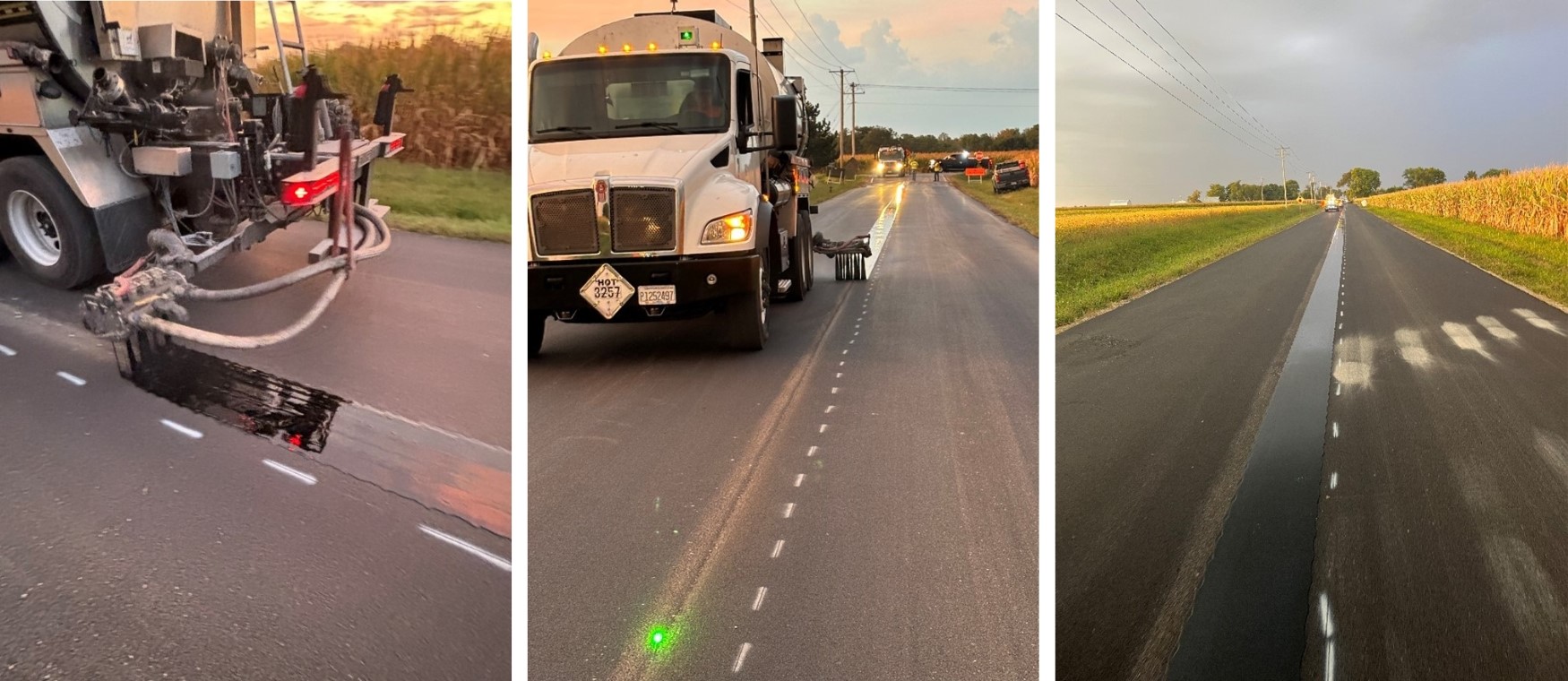

On a September morning at 6:30 am, Evergreen applied VRAM/LJS to a 3.56-mile stretch of County Highway 5 in Shelbyville County, Illinois. The VRAM was sprayed in an 18-inch wide band on a fresh binder course at the location of the road’s future centerline joint, just before the HMA paving began. A total of 3360 gallons of J-Band were applied over 19,250 feet.

Personnel present included Troy from Howell Paving Inc., Dustin, Jeff, Nate and Blake from Evergreen Roadworks, and Cody and Nathan from Asphalt Materials Inc.

By 10:00 am, paving began. Within just 30 minutes of the J-Band application, the road was ready for construction traffic.

The surface course for this project was a 1.5-inch IL 9.5mm Mix CN70, laid using a CAT AP 1055 paver. For the rolling operation, Howell used (2) Volvo Compactors DD120C in tandem, completing 7 passes in vibratory mode. The finishing rollers – a Hamm HP 280 pneumatic tire roller and Hamm HD+110 roller drum – made nine passes in vibratory mode.

During the paving process, the heat from the HMA and pressure from the rolling operation cause the J-Band to migrate upward, filling air voids from the bottom up. This significantly reduces permeability in the pavement and extends the joints’ life three-fold.

HMA paved over the VRAM. The clean track marks show J-Band’s non-tracking quality

In addition to creating more durable roads, VRAM delivers an unexpected safety benefit: the elimination of density testing at the joint. By applying a VRAM below the joint, pavement permeability is proven to reach zero, or near zero. With the joint compacted by the same roller pattern as the rest of the mat, there is no need for agencies to test for density at the joint.

As per VRAM’s specification, “The area 1.0 ft on either side of the longitudinal joint will be excluded from density measurement and pay adjustment.” This eliminates the need for pavement cores, which keeps workers away from the centerline, reducing the risk of accidents. For more information on density testing, check out this resource.

Rumble strips are an essential safety measure on busy roadways, altering drivers when they veer too close to oncoming traffic, or the edge of the road. However, rumble strips can also reduce the longevity of the pavement, especially along the already vulnerable longitudinal joints, because their grooves commonly collect water.

Applying J-Band under rumble strips is a proactive step toward preserving both the joint and the rumble strip itself. Studies have shown that cores with VRAM under rumble strips have significantly higher cracking resistance, ensuring that rumble strips remain effective for longer.

1. Preservation of Rumble Strips: J-Band extends the life of rumble strips, keeping this crucial safety feature intact and effective for motorists.

2. Density Testing Is Waived: By eliminating density testing at the joint, road workers are kept safer, avoiding the risks of working near the centerline.

3. Reduction in Maintenance Work: By preventing cracks and potholes, VRAM reduces the need for hazardous maintenance tasks, like crack sealing and pothole filling near the centerline, while also deferring major road reconstruction.

Ultimately, the application of J-Band extends the life of longitudinal joints, which in turn extends the life of the entire pavement. It saves time, money and more importantly, lives.

To learn more about how a VRAM can improve the safety and durability of your road network, visit thejointsolution.com or contact us today.

J-Band® is a registered trademark of Asphalt Materials, Inc. (AMI). J-Band® was created in the labs of the Heritage Research Group (HRG) and is a product of AMI.